Ansi Asq Z1 4 Pdf

Ansi z1.4-1993, table i, sample size code letters special levels general levels lot size shipping s-1 s-2 s-3 s-4 i ii ansi z1.4-1993, table iii-a, aql s for double. Ansi Asq Z1 4 1993 Pdf Sampling Procedures and Tables for Inspection by Attributes This standard is an acceptance sampling system to be used with switching rules on a continuing stream of lots for AQL specified.

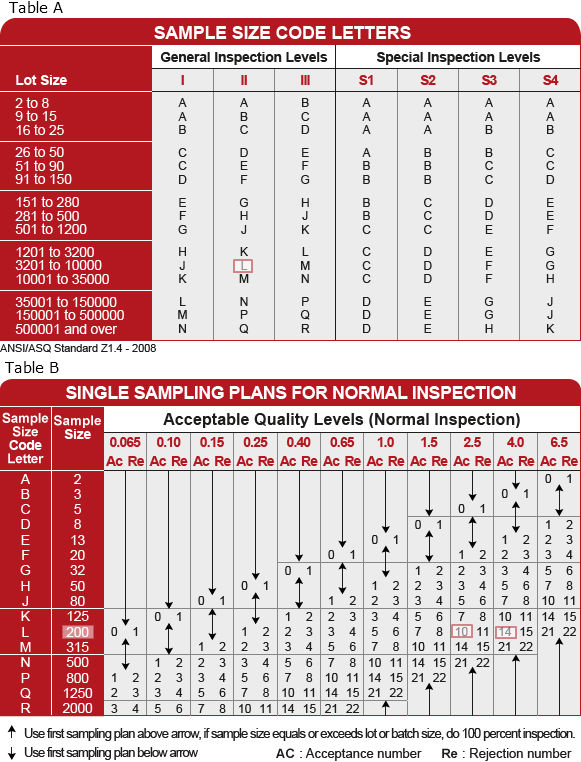

ANSIASQZRSampling Procedures and Tables for Inspection by Attributes-Sampling Procedures and Tables for Inspection by Attributes is an. ANSI/ASQ Z (R) Sampling Procedures and Tables for Inspection by Attributes Sampling Procedures and Tables for Inspection by Attributes is an. How to read the “ANSI tables”, aka “AQL tables”. Source: Mil-Std E, replaced by commercial standards: ISO, ANSI/ASQ Z, NF, BS

| Author: | Goltitaur Arashilmaran |

| Country: | Syria |

| Language: | English (Spanish) |

| Genre: | Marketing |

| Published (Last): | 1 January 2008 |

| Pages: | 322 |

| PDF File Size: | 19.93 Mb |

| ePub File Size: | 7.35 Mb |

| ISBN: | 208-7-94625-905-7 |

| Downloads: | 33404 |

| Price: | Free* [*Free Regsitration Required] |

| Uploader: | Dalmaran |

Learn more about visual inspection here. For more information about inspection, please view the resources found here. Need more than one copy? You can download and open this file to your own computer but DRM prevents opening this file on another computer, including a networked server.

Difference between ANSI/ASQC and ANSI/ASQ

This standard is also aqs to be included in Standards Subscriptions. I can decide to chose the number of rolls to sample from using the tables given in Z1. Some interpret it to mean if a lot has AQL percent defective or less, a lot would have a high probability of being accepted based on the sampling plan.

It is expected that the product quality level will be less than the AQL to avoid excessive non-accepted lots. This is also what was intended by the creators of the sampling scheme.

If it falls on an arrow does it mean that I have to change to the next sample size based on where the arrow points? Question I am confused about the values used for AQLs. It is important to understand what you are doing when using sampling plans, what they are and the protection you are trying to ensure. Thus, the important step is to determine the AQL.

ANSI/ASQ Z1.4-2003 and ANSI/ASQ Z1.9-2003

This point is not FDA but legalese. Already Subscribed to this document.

Add to Alert PDF. Page 1 Page 2 … Page z14. Next page. Initially you start at normal inspection, and can move to either tightened or reduced inspection depending on how lots are dispositioned.

Squeglia available from ASQ has been widely adopted for this reason. Where do these values come from and what do they mean? My question is about sampling aluminium foils, films used in packaging and sticker labels received in rolls which are wound around a core.

Although individual lots with quality as bad as the AQL can be accepted with fairly high probability, the designation of an AQL does not suggest that this is necessarily a desirable quality level.

The FDA requirement is that the plan be statistically valid. I would like to confirm if ASQ Z1. Which is correct or more appropriate to reflect supplier quality? The standard does not specify the probability of acceptance explicitly. This standard is also available in these packages:. Is it acceptable to select a specific plan tightened, normal or reduced and use it without the switching rules?

Your Alert Profile lists the documents that will be monitored. Standards Subscriptions from ANSI provides a money-saving, multi-user solution for accessing standards. The switching rules are there to protect the producer when the product is running very well or it has problems.

Then you select the sample size to provide the level of protection you are striving to ensure.

Starting at code letter D, move across that row until you intersect at the AQL 0. If you are using Z1. /grid-2-free-download-torrent.html. In other words, the process is stable over time.

If the acceptance number has been exceededbut the rejection number has not been reached, accept the lot, but reinstate normal inspection see Please first log in with a verified email before subscribing to alerts. The technical definition of AQL is the quality level that is the worst tolerable process average when a continuing series of lots is submitted for acceptance sampling.

Based on Figure 1 of the standard, the determination to move amongst the levels can be ascertained. Standards Subsctiption may be the perfect solution.

Adq second question is if I have a batch that passes acceptance sampling but at a subsequent downstream process a defect being inspected for by the upstream acceptance sampling inspection is found how do I determine if the lot is acceptable?

Most 10 Related

ANSI ASQC Z1.4-2008 PDF

This standard is a revision of ANSI/ASQC Z,. “Sampling Procedures and Tables for Inspection by. Attributes.” Beyond editorial refinements, only the. Know the switching rules for ANSI/ASQ Z Categorize the various sampling plan systems in terms of lot-by-lot, continuous production, attributes or variables. ANSI/ASQ Z Sampling Procedures and Tables for Inspection By. Attributes The FDA recognizes ANSI/ASQ Z as a General consensus standard.

| Author: | Zulugor Negore |

| Country: | Myanmar |

| Language: | English (Spanish) |

| Genre: | Photos |

| Published (Last): | 21 July 2017 |

| Pages: | 412 |

| PDF File Size: | 10.88 Mb |

| ePub File Size: | 2.3 Mb |

| ISBN: | 338-7-21538-248-7 |

| Downloads: | 97554 |

| Price: | Free* [*Free Regsitration Required] |

| Uploader: | Mezizshura |

Production is at a steady rate; and d. Acceptance Sampling With Rectification When Inspection Errors Are Present, Journal of Quality Technology, open access In ascq paper the authors consider the problem of estimating the number of nonconformances remaining in outgoing lots after acceptance sampling with rectification when inspection errors can occur.

ANSI/ASQ Z– (R): Sampling Procedures and Tables for Inspection by Attributes ASQ

Under reduced inspection, the sampling procedure may terminate without making a decision. Also, please understand that the tables in the standard are not exact value for AQL.

The product shall be assembled into identi? The curves shown are for single sampling; curves for double and multiple sampling are matched as closely as practicable.

It worked pretty well with the suppliers we had. If my AQL is 0. The AQL is the quality level that is anxi worst tolerable process average when a continuing series of lots is submitted for acceptance sampling. Inspection under the provisions of this standard shall not be resumed until corrective action has been taken.

Steven Walfish Secretary, U. The formation of the lots or batches, lot or batch size, and the manner in which each lot or batch is to be presented and identi? That is the pure definition of the alpha risk. Once on tightened inspection, unless corrective action is taken to improve product quality, it is very likely that the rule requiring discontinuance of sampling inspection will be invoked. If the AQL 1. Sample sizes are designated by code letters. An American National Standard is intended as a guide to aid the manufacturer, the consumer, and the general public.

Sorry, your blog cannot share posts by email. The number of units of product in the sample is the sample size. If I have one lot that fails Acceptance sampling and I am trying to bound the issue is it suitable to bound it to the one affected lot if the lot before and after pass or do I need to carry out additional sampling.

ANSI/ASQ Z1.4–2003 (R2013): Sampling Procedures and Tables for Inspection by Attributes

Ansi Asq Z1 4 2013 Pdf

The unit of product may or may not be the same as the unit of purchase, supply, production, or shipment. The supplier may be required at the discretion of the responsible authority to inspect every unit of the lot or batch for designated classes of nonconformities. But prior to doing that, we certified our suppliers by going to their facility and performing a process audit to make sure that the process was meeting our requirements.

Subscription pricing is determined by: Could you please add another layer to your response? The extent of nonconformance of product shall be expressed either in terms of percent nonconforming or in terms of nonconformities per hundred units. Use double sampling plan above or alternatively use code letter D. If that is not possible or practical, then percent inspection using a quick, inexpensive, and effective method permits you to avoid uncertainties with sampling.

Ansi Asq Z1 4 2008 Pdf

Z inspection levels –

When reduced inspection is in effect, normal inspection shall be instituted if any of the following occur on original inspection: Learn aasqc about sampling with open access articles from ASQ publications: Table X-D—Tables for sample size code letter: We have a number of different defects that fall into an AQL of 1.

Can I get further explanation of how one z1.4–2008 justify that less discrimination is needed? If you can assume that the data collected is representative of all months, then you should be O.

If the inspection method requires lot sampling, then all of the basic lot sampling guidelines apply. Normal inspection ans be used at the start of inspection unless otherwise directed by the responsible authority. In general, the function of such classi? Or does it remain at units?